A simple guideline for beginner and screen printing methods testing for product development purpose, required materials and equipment are shown below. for details, please contact us.

-

"Polyester and stainless-steel screens are available, and polyester screens are commonly used.Range of 70-mesh to 420-mesh can be select according to the fineness of printing image 200-mesh to 300-mesh are used for general printing."

※Mesh is the number of fibers per inch. -

Printing image should be located at inner area of stencil size 40% or less. please decide stencil frame size under this criteria. Small printing area against frame size produces better size stability.

※idea is under 20% -

"Beautiful printing can be performed by securing a clearance of 1 mm to 3 mm between each substrate and printing plate without bringing them into contact during printing.Dimensional stability deteriorates if the clearance is too large. To secure the clearance, the WHT printing table and bridge holder are necessery."

-

"Substrate might stick to stencil due to ink viscosity, and cause blurring after printing. Vacuum motor suctioning is used to fix each substrate on the printing table.Our WHT printing table and HPT printing table are equipped with the vacuum pump device."

-

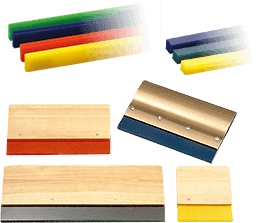

"Squeegee blades are commonly made with urethane. Printed results vary depending on the blade hardness. Soft blades result in thick coating with large amount of ink, and hard blades result in sharp printing with a small amount of ink coming out. As a guide, squeegees are color-coded by respective hardness: green (soft (65°)), blue (medium-hard (73°)), and yellow (hard (83°)).Select the squeegee length 5 cm to 10 cm longer than the width of the print image.If it is too short, printing pressure is released at the edges, and if it is too long, the stencil is stressed, image may distorted."

-

"Most inks and pastes need to be stirred to control viscosity by using an ink mixing board and ink spatula before printing.Select according to the print target and the purpose of printing. "

-

Screen printing is mostly performed with thick ink and needs time for drying. Drying rack is necessary for drying. It is selectable by substrate size and weight.

-

Solvent-resistant MINOGLOVE to protect skin from ink, paste, and solvent; MINOSTAT to eliminate static electricity from substrates; screen spray to remove clogging of ink on stencil; alignment labels to align each substrate on the printing table, etc.

MINO INTERNATIONAL LTD.

Office Hour 9:00〜12:00/13:00〜17:00

(Monday to Friday, excluding National holiday)